tpPLC software is an efficient and stable industrial automation software that is compatible with PLC equipment from a variety of different manufacturers. It achieves efficient data transmission and management through advanced data transmission technology. It has a simple operation interface and rich functional modules, which can monitor the operating status and working parameters of PLC equipment in real time, and provides comprehensive data collection, analysis and alarm notification functions to help users find and solve problems in a timely manner.

Software features

Efficient and stable: tpPLC software uses advanced data encoding and decoding technology to achieve efficient and stable data transmission, greatly improving the data transmission speed and stability.

Strong compatibility: tpPLC software supports a variety of PLC devices from different manufacturers, and can achieve unified management and control of various hardware devices, making it convenient for users to conduct centralized management and maintenance.

Safe and reliable: tpPLC software uses multi-layer data encryption technology to ensure the security of data transmission, prevent data from being tampered with or stolen, and ensure user data security.

Easy to operate: The tpPLC software interface is simple and intuitive, with clear functional divisions and simple and easy operation. Even beginners can get started quickly and improve work efficiency.

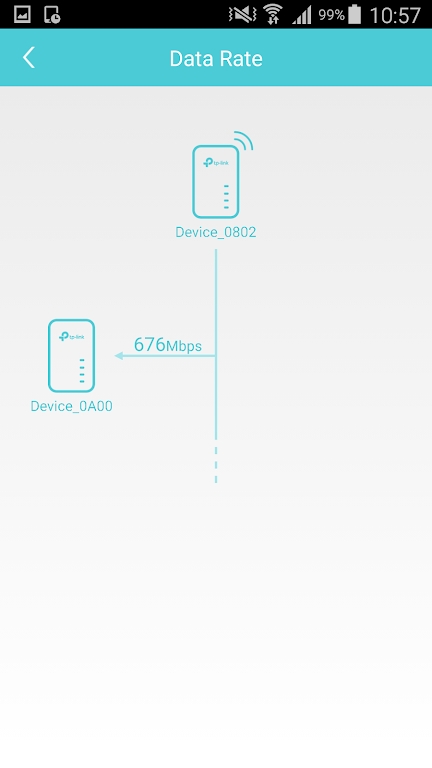

Real-time monitoring: tpPLC software can monitor the operating status and working parameters of PLC equipment in real time, provide detailed reports and statistical analysis, and help users find and solve problems in a timely manner.

Software function

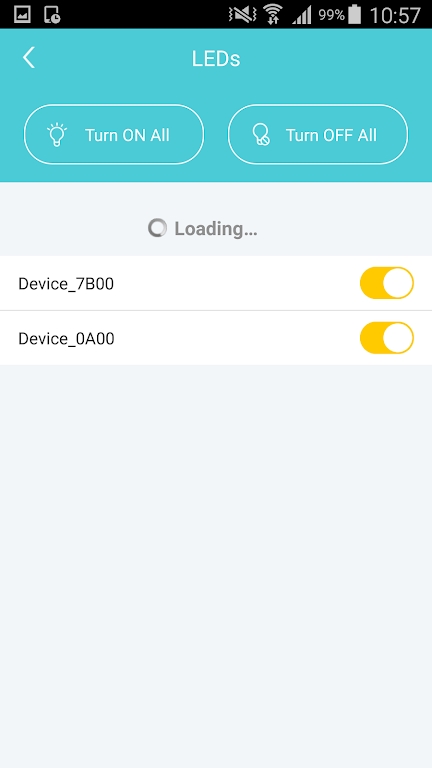

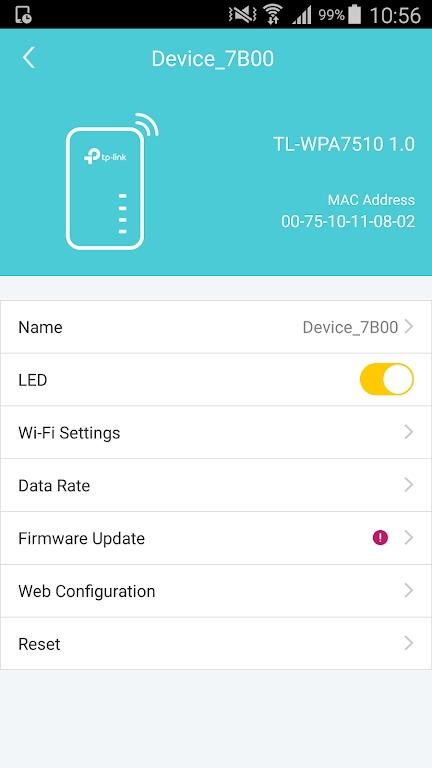

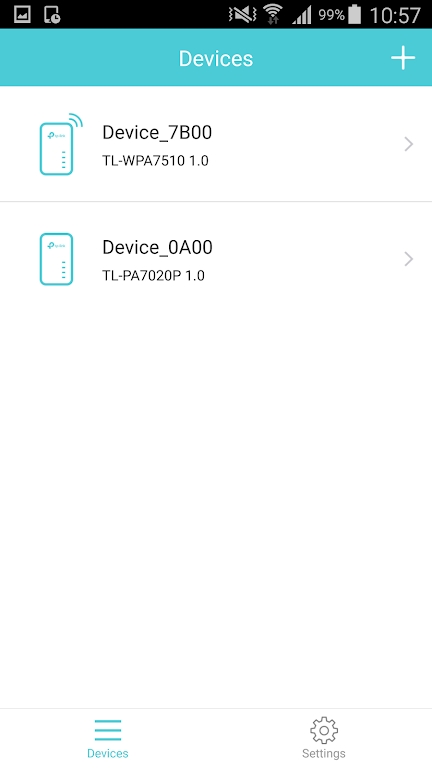

PLC equipment management: Supports adding, deleting, and modifying PLC equipment online to realize real-time monitoring and management of equipment status, parameters, etc.

Data collection and analysis: It can collect and analyze various data of PLC equipment in real time, and provide a variety of data visualization display methods to help users better understand the operating status of the equipment.

Remote control and operation: Supports the control and operation of remote PLC equipment through the network, realizing remote switching, remote configuration and other functions to facilitate users' remote management.

Alarm and notification: It can monitor abnormal conditions of PLC equipment and send alarm information to users in a timely manner. It supports multiple alarm methods to ensure that users can take timely measures to solve problems.

Data storage and backup: Provides data storage and backup functions. Users can archive and back up the operating data of PLC equipment to facilitate future data analysis and comparison.

Similar Apps